On July 18th, the Protostudios team, along with Jerry Wang, a graduate student working on Dr. Jun Wang's USDA Soil Sensor project, visited Hawkeye Molding Company, Inc. in Roland, Iowa. Keith Miller, their Operations Manager, gave us a tour of their injection molding operation.

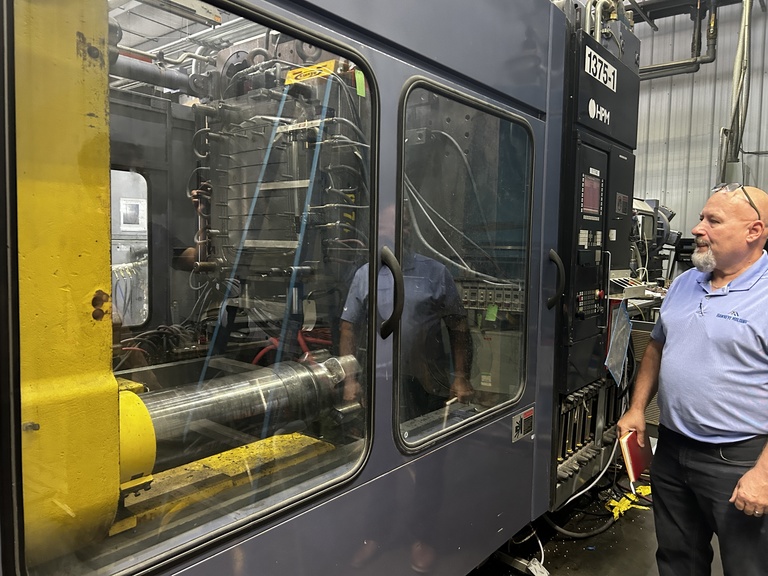

We learned about their material capabilities, diverse machinery, and saw their largest injection molding machine, which has a tonnage of 1375 tons!

Hawkeye Molding specializes in Iowa-made custom injection molded parts & products serving the industries of appliance, agriculture, furniture, industrial, lighting, and manufacturing components.

Upon arriving at Hawkeye Molding, we were welcomed by Mr. Keith Miller, their Operations Manager, who began with an overview of the company’s operations, highlighting the importance of design and prototyping—core elements of Protostudios—in their manufacturing processes.

The tour started on the manufacturing floor, where we observed the intricacies of injection molding. We saw raw materials transformed into finished products through precise, controlled processes and engaged with technicians who shared valuable insights, deepening their understanding of real-world manufacturing challenges.

Protostudios emphasized real-world learning, and the visit to Hawkeye Molding exemplified this approach. By interacting with professionals and seeing industrial machines up close, the students connected their academic studies to industry demands. We left with a deeper understanding of the molding process and a renewed sense of purpose, knowing our Protostudios skills would be vital for the future careers. Thank you, Hawkeye Molding, for the insightful visit!